Offshore Mooring Systems Are of Critical Importance

Offshore wind turbine installations have been already operating for more than decades in the harsh marine environment. Professionals are continuously investing time and efforts to make their design, installation and maintenance as reliable and simple as possible since the investments are usually significant and the projects – technically demanding and time-consuming.

Floating platforms are largely deployed in the oil and gas sector and start becoming a highlight as well in the marine renewable energy sector. Concepts for platform designs and mooring systems for offshore wind, however, remain very challenging, since the installation should fulfill countless requirements for dynamic characteristics and loads.

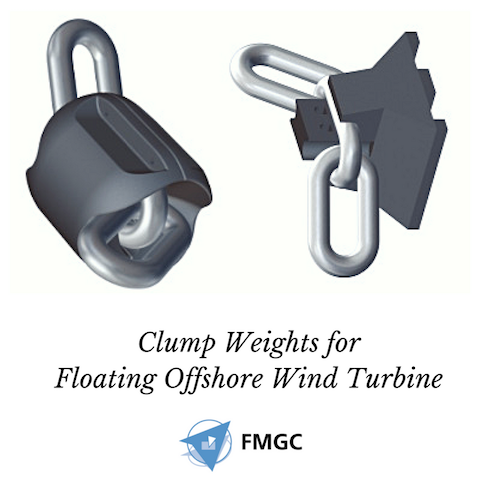

FMGC is the European leader in the manufacture of cast iron counterweights. During the last 4 years the foundry has diversified its offer and applied its expertise in ballast solutions and innovative concepts to the Marine Renewable Energy Sector. Today the company supplies the marine industry with a large scale of products. Clump weights for floating offshore wind turbines have been especially designed and manufactured to fit to the stringent requirements of the sector.

The Rise of the Offshore Wind Power

Offshore wind turbines are placed in the ocean on the continental shelf to harvest wind energy and generate electricity. Since the demand for global energy keeps steadily increasing, renewable energy sources move in the spotlight. Offshore floating wind power is considered as one of the most promising sources of sustainable energy. The abundance of space and the consistent wind resources guarantee the high energy output.

The Floating Offshore Wind Power Installations

Floating offshore wind power installations might be a big game changer for countries with few shallow-water sites. Floating installations can be placed in water deeper than 50 meters and offer an opportunity for large-scale offshore wind deployment in areas where the winds are stronger and regular . These constructions can benefit from existing offshore wind technologies and in the same way will add value in the further development of the sector by challenging manufacturers. Furthermore, floating designs don’t damage the sea bed as fixed ones might do, are easier to install.

In general floating structures with new promising designs can open vast new areas and markets currently unavailable for offshore wind.

There are a couple of critical environmental conditions that should be carefully taken into account when designing and manufacturing a floating offshore wind turbine. Some of these include wind speed and turbulence, currents, waves and tides, marine growth, air density and others.

Floating Is Possible Only When Mooring Is Reliable

A floating offshore wind turbine is kept in place by a sophisticated mooring system, taking all permanent, variable and environmental loads. Permanent loads include the weight of the turbine’s components as the weight of rotor components, housing structure, machinery, ballast and others. The variable loads are the ones that might change during operation and the environmental ones encompass the waves and currents.

To be as robust, the system should be properly designed, manufactured, installed and maintained. A mooring installation is usually made of a mooring line, connecting an anchor on the seafloor to a floating structure. There are 6 common mooring systems deployed until now in the industry. These are catenary, taut-leg, semi-taut, spread, single point and dynamic positioning.

A reliable mooring system secures the status of an offshore wind power installation as a trusted source of renewable energy.

Turbine designs keep varying in size and shapes to accommodate improved functionalities. Their installation gets even more expensive and robust and proven technology is essential to guarantee investors’ confidence and reliable returns. FMGC is aware of the sector’s challenges and the foundry’s main goal is to provide the industry with cost efficient products of highest quality.

FMGC Manufactures High-Quality Cast Iron Clump Weights for Floating Offshore Wind Turbines

FMGC grey cast iron clump weights are designed to be positioned on the mooring lines in order to ensure the restoring forces without resort to expensive solutions or longer mooring lines length.

To meet as close as possible the different mooring design the clump weights are available:

- in a “distributed” configuration where the clump weights are spread along a segment of the mooring line. This design ensures a proportional recovery of the loads and could be positioned on the touchdown point;

- in a “mutualized” configuration where an single clump weight (Few to hundreds of tons) is positioned closer to the platform to ensure the restoring forces and broke the mooring line tension.

Moreover FMGC products can be customized to suit the individual requirement of every mooring system based on the target weight, the chain line diameter and the available installation means. Besides, with clump weights, the foundry supplies the MRE industry with gravity anchors and static ballast.

Consult FMGC studies on the behavior of cast iron in marine environment

A trusted partner of the Marine Renewable Energy sector, FMGC is committed to driving the industry’s development through the creation of innovative ballast solutions. A sustainable offshore wind marker is only possible if experience meets ingeniosity at minimized costs and risks to result in reliability. Our goal is to help professionals to overcome the challenges with greater safety and higher output.