The protection of submarine power cables is of critical importance for the proper transport of electricity onshore. The expanding world energy consumption and the increasing world environmental awareness raise the importance of marine renewable energies and international power grid connections. Submarine power cables are the fastest and most efficient way to distribute energy. Furthermore, they build the basis of the global telecommunications network, world’s financial and security systems.

The repair of a broken or a damage cable is a laborious, slow and expensive operation, so it is in the interest of every state to protect subsea cables.

The threats for submarine cables can be classified in two main groups. The first one encompasses natural disasters, fishing and shipping activities and the second one – improper installation / laying of the cable. Realizing the critical importance of submarine power cables, engineers are constantly improving the methods for their protection.

There are several known techniques for submarine power cables protection as direct burial, concrete mattresses, rock trenching, concrete slabs or cast iron half pipes, assembled onto the cable by divers after laying it. However, all conventional methods show some disadvantages at some point in terms of corrosion, installation or cost efficiency. Most of them are costly, slow and only suitable for a limited length of the cable route. Additional challenges may include thin sand layer, which affects the required burial depth, forbidden access for large heavy duty installation vessels or danger of crossing existing cables or pipes.

The New Solution

The consortium IBOCS (Iron Ballast Offshore Cable Solution) was established on 1st of April, 2015. The participants of this R&D collaborative project are:

- FMGC as an industrial partner

- INNOSEA as an engineering partner and

- GeM (the Research Institute of Civil Engineering and Mechanics at the University of Nantes) as a scientific partner

The goal of IBOCS is to respond to the challenges, facing the MRE sector by optimizing the installation, stabilization and protection of subsea power cables. With the support of INNOSEA and GEM, FMGC has designed and manufactured protecting and ballasting shells to stabilize subsea conducts (cables, pipes) and a semi-automatic installation equipment.

➤ ABOUT PROTECTING AND BALLASTING SHELLS

This is a tailor-made solution, from the design of the shell depending on the needs of the project until the supply of the laying device.

FMGC cast iron protecting and ballasting shells are a cost-efficient product with a hydrodynamic design, offering an increase in the bend radius and a transfer of tensile forces during installation. The shells provide sufficient weight to stabilize the cable on the ground without external elements as concrete mattress or rock-dumping.

➤ WATCH THE INSTALLATION OF THE SABELLA D10 SUBMARINE CABLE, EQUIPPED WITH FMGC BALLASTING SHELLS

The four main advantages of FMGC protecting and ballasting shells can be summarized as follow:

Why Choosing FMGC Protecting and Ballasting Shells for Submarine Power Cables?

Time Saving

FMGC shells can be installed at the same time as the cable, which means that only one installation operation is required. Furthermore, the dedicated laying device increases the installation speed. Compared to rock dumping, where a cable is installed in a pre-dredged trench and covered with previously excavated material, this installation appears far easier and less laborious.

Economic Gain

The weight of the FMGC protecting and ballasting shells is adjustable, depending on the specific needs of the submarine power cable. They stabilize the cable, while at the same time they protect it. Therefore, no additional support techniques as rock dumping or concrete mattress are required. FMGC shells are installed simply with the semi-automatic installation equipment without heavy-duty vessels.

Reliability

According to In Vivo Environment (Marine Environment and Ocenographic Consultancy Services) that was assigned from FMGC to conduct a research on the exact impact of gray cast iron on the marine environment, cast iron stays relatively unaffected by corrosion. The shells are dimensioned based on maximal corrosion hypothesis, so that can offer a long-lasting solution.

➤ DISCOVER THE BENEFITS OF CAST IRON FOR MRE SOLUTIONS

➤ WHAT IS THE IMPACT OF GRAY CAST IRON ON THE MARINE ENVIRONMENT?

➤ HOW TO HANDLE CORROSION OF CAST IRON IN MARINE ENVIRONMENT?

Environmentally Friendly

Since there is no need to trench or clear sediments from the seabed, the installation of FMGC protecting and ballasting shells has less to no impact on the soil. All FMGC cast iron solutions are made of 100% recycled materials, sourced principally in France and all finished products are fully recyclable at the end of the project.

➤ READ MORE ABOUT THE ADVANTAGES OF FMGC PROTECTING AND BALLASTING SHELLS

Technical Specifications of FMGC Protecting and Ballasting Shells

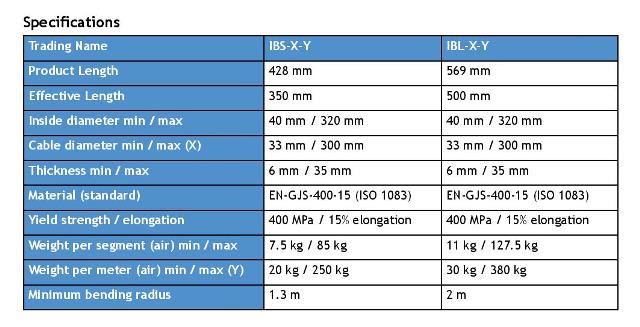

FMGC cast iron ballasting shells provide most reliable and robust submarine power cable protection. They are especially designed to resist high impact, abrasion and corrosion and to withstand the harshness of marine environments.

The product is suitable for different types of cables: from telecom cable of 20mm to export cable of 300mm. Since all shells have the same joint system, our engineers can easily adapt the kilograms required for each cable segment (from 30kg/m to 250kg/m), depending on the specific seabed conditions. Thus, for the same diameter of cable, we can easily alternate the type of shells along the cable route.

Furthermore, in collaboration with INNOSEA, FMGC can calculate and analyze the required ballast weight for the cable, based on metocean and soil data and thus, identify potential weight and cost savings.