Additive Manufacturing

The Farinia Group, specializing in the transformation of materials and focused on innovation, has naturally turned to additive manufacturing.

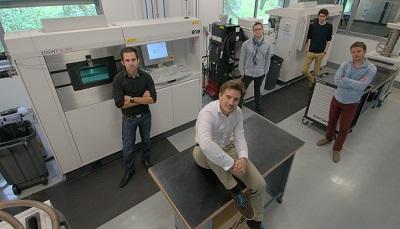

Farinia: A Pioneer of 3D Printing

The Farinia group, specializing in the transformation of materials and focused on innovation, has naturally turned to additive manufacturing.

Spartacus3D, our new start-up dedicated to additive manufacturing, offers tailor-made solutions that combine expertise and know-how in engineering.

Using high-quality metal powder, selective laser melting allows us to produce optimized parts with complex shapes, especially for the aerospace, space and automotive industries.

How do we make our parts at Spartacus3D?

Metal additive manufacturing consists of successively depositing and solidifying thin layers of metal powders. There are different technologies, such as selective laser melting - known as "Direct Metal Laser Sintering" (DMLS) or "Selective Laser Melting" (SLM) in English - which uses thermal energy in a focused manner on surface of a powder bed in order to melt the material and merge it as it cools.

The process results in components close to the final shape, requiring little or no finishing or machining operations. The parts generally have a good surface finish, interesting geometric precision as well as reliable mechanical performance.