FMGC Cast Iron Ballast Stabilizes The “HydroQuest Ocean” Tidal Turbine

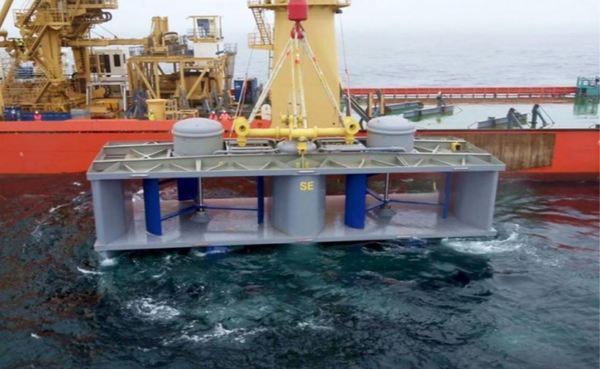

HydroQuest, in partnership with CMN (Constructions Mécaniques de Normandie) has deployed on April, 26 and 28 a 1 Mw tidal turbine in the waters near Paimpol-Bréhat in Brittany, France. The vertical axis turbine will be kept in place using a gravity-based foundation.

FMGC was assigned by CMN (and HydroQuest) with the design, development, manufacturing and delivery of the gravity base ballast and associated accessories, aiming at stabilizing the tidal turbine and preventing it from overturning or sliding.

The successful deployment of the HydroQuest Ocean ballasting system developed by FMGC consisted of the following development and validation steps:

1. Thanks to a close collaboration with numerous iterations with CMN and HydroQuest, FMGC has developed a complete ballasting system contributing to an important reduction of the substructure costs and volumes.

2. FMGC has based the ballasting system on an assembly of hundreds of tons ballast stacked around a steel insert. FMGC has been responsible as well for the design and validation of the inserts.

The steel inserts ensure the most efficient assembly of the ballasting system. At the same time they ease as well the lifting and installation operations and thus limit the mobilisation time of the vessels and teams, both on dock and offshore.

3. FEA analysis has been performed on the inserts in order to confirm their ability to meet the mechanical solicitations in operational conditions. The results have met all the expectations and the first pieces have been manufactured.

Once the steel inserts have been manufactured, FMGC has achieved another proof load tests with more than 450 tons of load applied during the test process.

4. In early April FMGC has also achieved a first assembly of the complete structure prior to the deployment of the tidal turbine and associated substructure. In less than one day the entire ballasting system has been assembled, positioned and locked, meeting all the expectations. Finally different control procedures have been performed to validate the height and inclination, confirming once again the conformity of the system, and its ability to be deployed.

FMGC has been really proud of being a part of this pioneer project and to support the customer from the basic design until the deployment of the ballasting system. The HydroQuest Ocean project confirms one more time the important role and efficiency of cast iron in offshore applications, but also how a tailored design developed in close collaboration with the developer ensure the efficiency and optimisation of the system, at every steps of the project.

FMGC has a proven track record in successfully deploying cast iron ballast for previous tidal projects such as Naval Energies, Sabella and Guinard Energies.