In the time of drastic environmental changes every industry seeks for new innovative solutions. When discussing the global warming, the energy sector inevitably comes to the fore. The efforts in minimizing the carbon dioxide levels in the atmosphere led to the invention of alternative energy sources. Besides wind and sun, the sea has been recently more and more explored in gaining energy naturally. Tidal stream systems are considered the energy technology of the future and although they are already several established designs, this industry is still in a development phase.

Every tidal stream system has two important components: a rotor with blades and generator and a fixed to the seabed foundation. Since each device needs to be held on station in a tidal flow, the tidal turbine foundation forms a significant part of the life-cycle cost and installation/maintenance plan. The biggest challenge comes from the fact that every configuration should be mounted on the seabed in a practical and cost-effective way, which is not evident since the installation usually occurs in hostile environment with strong currents.

There are plenty of environmental parameters that need to be considered before designing a tidal turbine foundation: tidal current, water depths, exposure and bathymetry. Also, a tidal turbine can not be fixed to the seabed anytime. There are special installation (or maintenance) windows based on the strength of the wind, the size of the tides waves and the seabed geology in general. Therefore every experienced engineer faces plenty of challenges while designing, installing and maintaining a tidal turbine foundation.

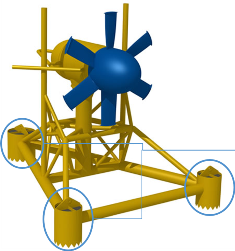

Up to the present day there are many applicable different ways to attach a tidal turbine to the seabed. All of them are quite expensive in terms of installation due to additional tooling, in- depth geological analysis and complicated configuration which requires short interval maintenance. The French company SABELLA was one of the first companies to recognize the need of alternative solutions. The tidal turbine technology of SABELLA unifies reliable simplicity with robust build. Besides many other improvements in the turbine body and mechanism, there is a revolutionary change in the way of how the turbine is fixed to the seabed and precisely without any penetration or damage of the sea floor. Resistant tidal turbine ballast made of gray cast iron forms the base of this new configuration. The turbine is simply mounted on it and placed on the seabed.

What are the benefits of the tidal turbine ballast compared to monopiles and other gravity-based foundations?

1. Design

The simple but robust design of the cast iron ballast significantly prolongs the life of the foundation. This configuration is theoretically unbreakable which leads to a long term survivability during storms or very strong currents where piled constructions can easily bend or break.

2. Installation

To drill a pile into the seabed is a time-consuming operation that requires very specific and expensive tooling. To apply this process for a whole tidal turbine farm is excessively difficult. Though the installation of another foundation might be slightly easier, it still remains dangerous and complicated compared to the installation of the SABELLA tidal turbine.

3. Impact and Snagging Loads

The tidal turbine ballast is made of gray cast iron which delivers best resistance against corrosion, impact or snagging and has much higher density than concrete. Cast iron has been proven itself as the material with the best mechanical properties in terms of protection.

4. Wave loadings

Since drilled piles are long-term installations, storm loadings on the device structure should be considered while designing it, in case the installation phase can not be completed within weather windows. On the one hand the installation of a tidal turbine with ballast base occurs much faster, on the other hand there is no need for an extra wave loadings solution incorporated at the design stage.

5. Cost

By combining easy installation with long lasting reliability, the tidal turbine ballast is obviously the most cost-efficient choice compared to all other existing applications.

6. Environment

The high density ballast is made of recycled steel. The carbon assessment of this process is positive and many studies have confirmed its environmental neutrality.

The tidal turbine ballast for the SABELLA new marine technology is designed and manufactured by FMGC – a leader with experience in the manufacture of cast iron counterweights for a wide range of industries. A team of experienced engineers has invented the revolutionary solution which guarantees resistance and low maintenance in a hostile environment with a difficult access.