Tidal power is a newer renewable energy resource than wind and solar power. Tidal turbines are considered one of the most promising technologies nowadays, since tides are more predictable and therefore financially more reliable than wind energy and solar power (which output depends on the weather forecast). The tidal turbine energy is a sustainable energy source that overrides any other alternative energy sources because of its practically inexhaustible tidal power controlled by the gravitational interaction between Earth's tides, Moon, Sun and Earth's rotation.

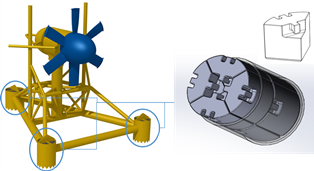

The tidal turbine looks like an underwater windmill and consists of blades, rotor, generator and a base. The way the base is fixed to the seabed plays a significant role in the entire system since it secures the stability of the device. Until now the most used foundations for prototype are rigid monopiles, drilled or hammered into the seabed, gravity foundations or floating structures, moored or anchors.

This is as a short overview of the existing tidal turbine foundations. Since this is an industry sector in continuous research and development, hybrid or entirely new solutions should always be considered.

Monopiles

- Water depth: up to 30 meters

- Benefits: simple design, easy fabrication, the most common one

- Drawbacks: possible bending and fatigue cracks, failures caused by welding defects, seabed penetration, installation is not permitted in certain areas due to environmental constraints

Gravity Foundations

- Water depth: 20 to 80 meters

- Benefits: easy installation, especially in places unreachable for installation vessels

- Drawbacks: concrete has too big volume, possible footprint damages and erosion

Floating Structures

- Water depth: from 80 meters

- Benefits: the only available solution for deeper waters

- Drawbacks: if moored or anchores prone to corrosion and wave loadings

Tripods with Buckets

- Water depth: from 20 to 50 meters

- Benefits: the bucket can be emptied for an easir installation

- Drawbacks: seabed penetration possible only in certain soil types

Suction buckets

- Water depth: from 0 to 25 meters

- Benefits: better bearing capacities

- Drawbacks: costly fabrication and difficult installation

The choice of a tidal turbine foundation depends on many factors. Environmental parameters as seabed type and water depth are crucial. All configurations mentioned above need in-depth geological analysis on the sea soil conditions. The surveys for drilling are the most expensive ones since the price grows proportional to the required depth. Cost is also a main problem for the installation process. Piles for example need construction vessels in order to be placed. These vessels are expensive machines which availability is always doubtful since they were designed to be employed in other industries. Besides installation vessels, human operating power is also required. In hostile environments the installation and maintenance windows are limited to 30 minutes during slack tides, which makes very difficult any kind of intervention.

Last but not least, all mentioned platforms have in a certain way a negative impact on the seabed and fish behaviour (they start avoiding the damaged area).

The new approach

The French company SABELLA decided to find a solution to face all these problems and to design a tidal turbine device's foundation that would overcome the drawbacks of the existing ones. The revolutionary device is attached to the seabed using completely new mechanism – tidal turbine ballast. The tidal turbine ballast is a gravity-based foundation but its tripod structure differentiates it from the standard gravity foundations. The tripod eliminates well-known gravity bases' negative environmental impact of the footprint. The material the ballast is made of plays a critical role. Gray cast iron has numerous advantages compared to concrete and enables steady support and reliable structure.

As an European leader in the manufacturing of cast iron counterweights with different sizes and shapes for a wide range of industries, FMGC has actively supported SABELLA in the design phase of the tidal turbine foundation and has manufactured the high density cast iron ballast.

This configuration doesn't require any in-depth geological analysis nor expensive surveys since it can be dropped on soft or hard surface. The installation process is also much easier because there is no need for human operational power or installation vessel. A common heavy-duty machine as a crane can accomplish the operation. Due to its simple but extremely robust design, this tidal turbine doesn't have basically any part of the foundation that could be damaged. Another common problem – the corrosion – is solved with the high resistant coating. The ballast base doesn't harm the seabed surface, nor disturb the fish migrations.

The tidal turbine ballast is a new promising technology to attach a tidal turbine to the seabed. This is a cost-efficient solution with simple and strong build, requiring low maintenance level and designed to operate in hostile environment with difficult access.