UPSET FORGING

Upset forging process makes it possible to obtain long parts with a complex end geometry. Discover our possibilities !

A LOCALISED DEFORMATION

Upset forging involves locally heating a metal bar and then, while holding it firmly with special tooling, applying pressure to the end of the bar in the direction of its axis to deform it.

The process allows the production of long parts with a forged end. Upset forging does not allow for as large a variation between the initial bar diameter and the forged head diameter as with the electro-upsetting process. It does, however, allow for much more complex geometries to be obtained as the deformation is carried out in several stages.

Upset forging is used to produce all types of long parts such as shafts, screws, piston rods and others for the automotive industry, public works, aeronautics and many other fields of application.

Setforge is one of the European specialists in this process. With a unique capacity on the market, we are able to forge monobloc parts that are almost 5 metres long and can weigh up to 600 kg!Kg !

PRODUCTION AND CHARACTERISTICS

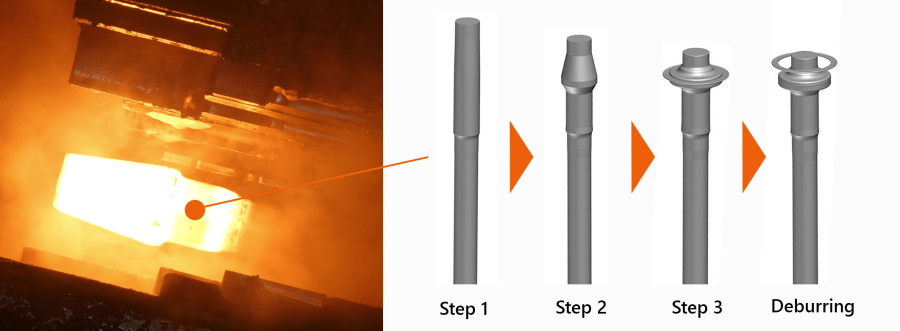

As an extension of hot forging, upset forging is a competitive process that can be adapted to high-volume production of elongated parts. The progressive stepwise deformation of the head allows the production of axisymmetric parts with complex geometry.

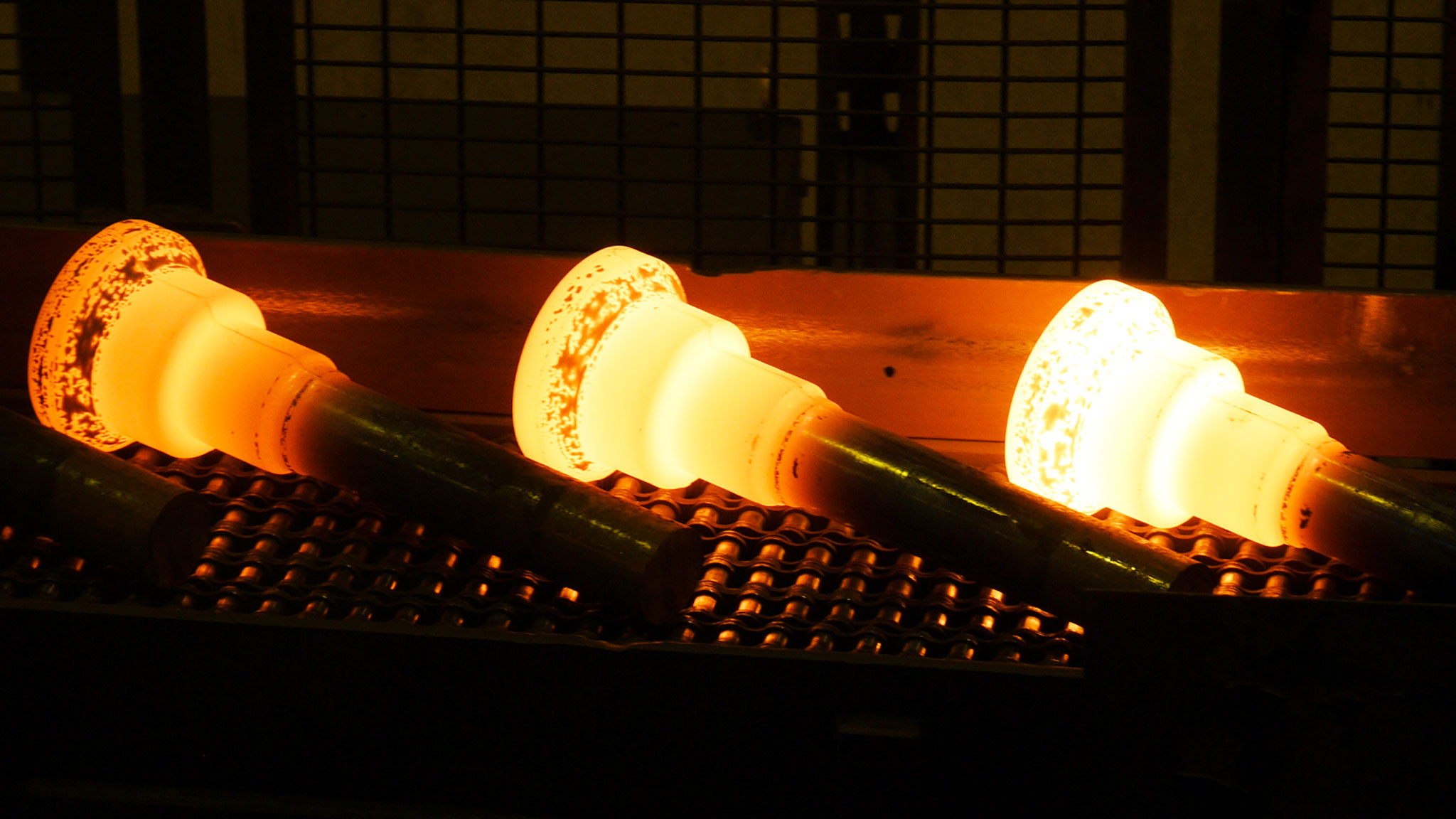

1-Heating

The slug is heated locally at the end. Several heating methods are available depending on the requirements of the final part:

GAS OR ELECTRIC OVEN

INDUCTION HEATING

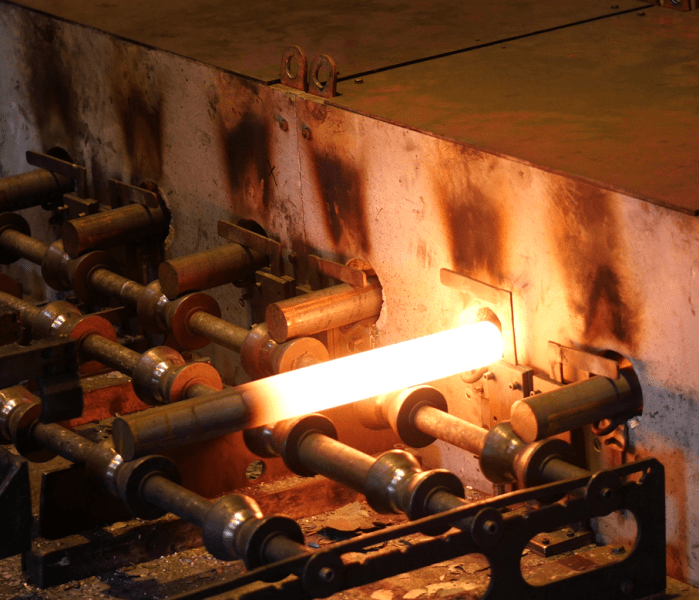

2 - Forging and finishing

After being heated, the slug is directly forged in a press.

A complex tooling will hold the billet and exert pressure in the direction of its axis. As in the example above, the deformation is progressive and allows a great dimensional control of the parts produced.

Once forged, the part is cooled in a cooling tunnel, either in ambient air or atmosphere, and then transferred to the heat treatment and machining operations.

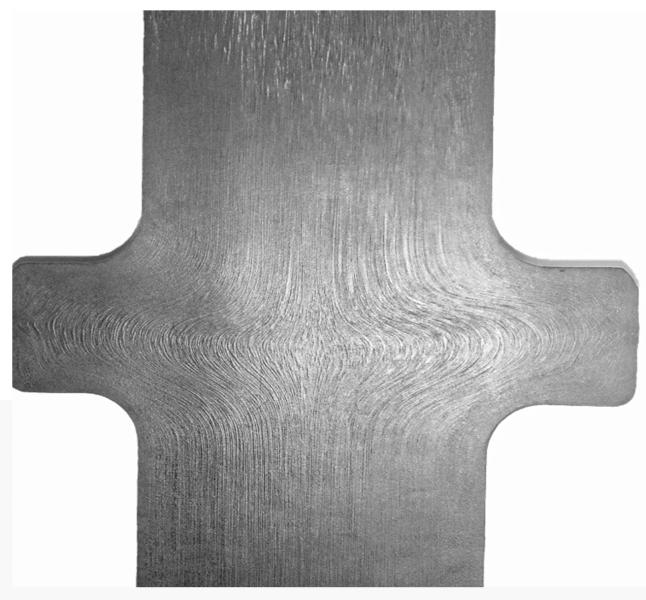

The metal fibre is clearly visible.

It follows the contours of the part, allowing for better fatigue resistance.

CHARACTERISTICS

Steel is composed of grains and intergranular impurities. During forming operations, in the steel mill and then in the forge, these grains and inclusions are deformed. The whole thing elongates in the direction of the deformation, forming what is known as the "grain flow" of the metal. To quantify this deformation, we speak of wrought iron, the rate of which is related to the initial section of the part in relation to its final section.

The orientation of this grain flow is of major importance for the mechanical strength of a part. Our know-how allows us to determine the optimal orientation of the fibre drawing according to the use and the mechanical stresses that the part will have to undergo.

These characteristics make it possible to obtain parts with very high mechanical performance that can be used for the most critical applications.

We are able to forge all types of materials by upsetting: steels, stainless steels, titanium, etc.

BENEFITS AND LIMITATIONS

STRUCTURAL INTEGRITY

Upset forging allows us to obtain long, single-piece parts that avoid any risk of cracking.

PERFORMANCE

The orientation of the fibres in the direction of the mechanical stresses allows for optimal fatigue resistance.

ENERGY SAVING

The process requires only partial heating of the plot and is therefore energy-efficient and low in CO2 emissions.

MATERIAL SAVINGS

The multi-stage forging process ensures that the final geometry of the part is closely matched.

REDUCTION OF MACHINING OPERATIONS

As close as possible to the final dimensions of the component, the forged part is easily machined.

DIMENSIONAL LIMITATION

Upset forging does not allow for as large a variation in diameter as the electro-upsetting process.

Setforge Barriol&Dallière

UPSET FORGING IN SETFORGE

Upset forging is one of the specialities of our company Setforge Barriol&Dallière, which is able to forge monobloc parts weighing almost 600 kg. A unique capacity on the market!

Our production includes a wide range of long parts such as transmission shafts, cylinder rods, screws, etc. for many sectors of activity and all production volumes.

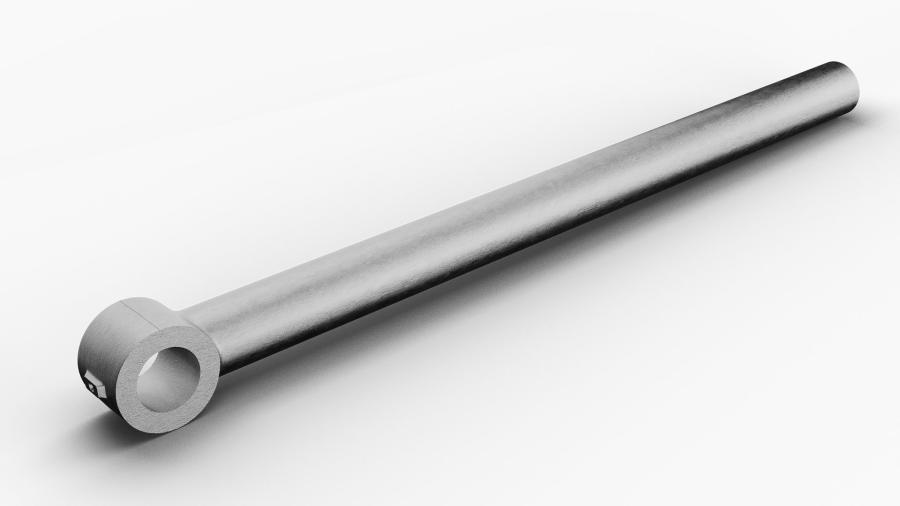

Drive shaft

TRUCK

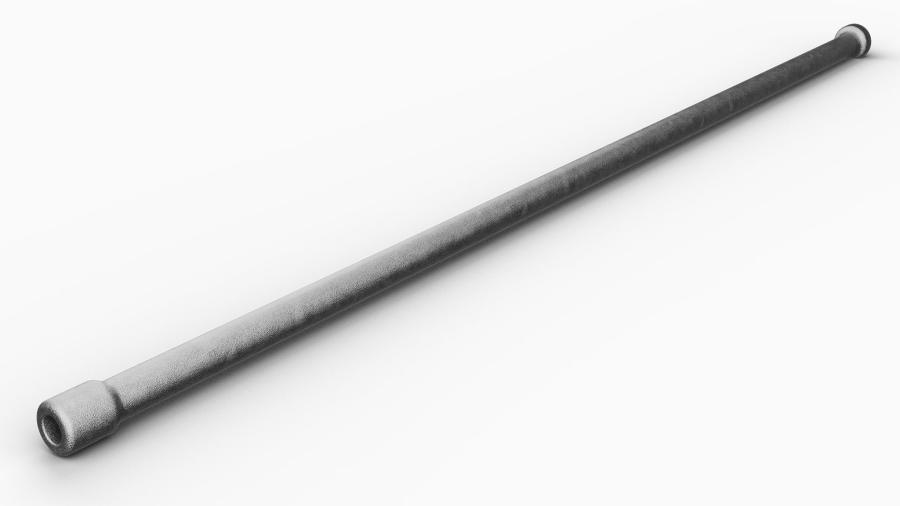

Cylinder rod

CONSTRUCTION

HTSA Screw

AEROSPACE

Pup Joint

OIL & GAS

Would you like to know more about upsetting forging?

OUR TEAMS ARE AT YOUR DISPOSAL!