Electrical upsetting

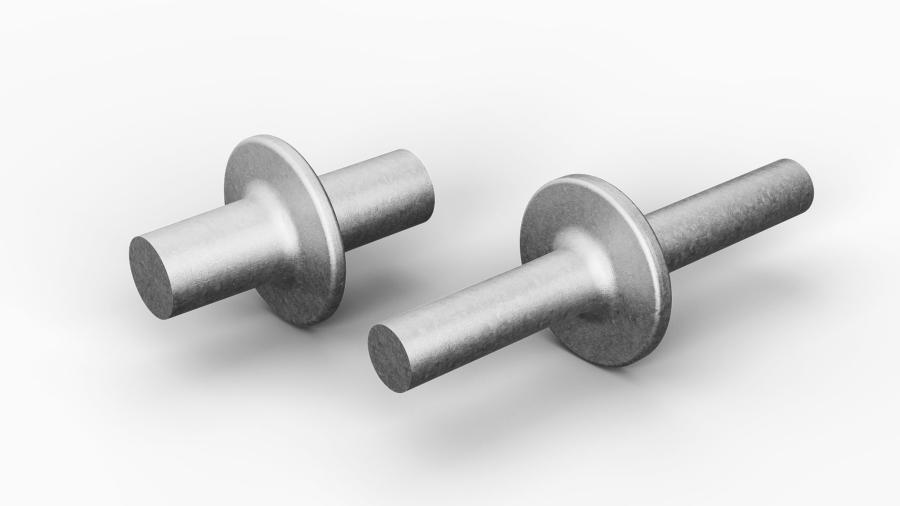

Electrical upsetting makes it possible to obtain long parts as flange shafts with consequent variations in diameter.

Localized deformation

The electrical upsetting consists in deforming a metal slug by applying an electric current by conduction while carrying out a material upsetting by pressure, in order to form an accumulation of material. This accumulation of material is then forged to obtain the desired shape. Electrical upsetting makes it possible to obtain flange parts having a large difference in diameter between the original diameter of the slug and the plate.

This process is used for the manufacture of monobloc transmission parts, shafts or couplings for the automobile, public works, aeronautics and in many other fields.

Setforge is one of the European specialists in this process. We are able to produce upset parts of all types up to 200 Kg for small, medium and large series.

PRODUCTION AND CHARACTERISTICS

Electrical upsetting is the only process that makes it possible to obtain such a large variation between the initial diameter of the bar and its plate.

The upset diameter can be 20 times larger than the section of the slug.

1-Heating of the preform

The slug is heated locally by applying a conduction through the application of an electric current.

Pressure is applied at the end of the bar in order to force the heated material to a state allowing plastic deformation. This will then accumulate at the other end of the slug.

2-Forging

The slug is immediately transferred to a die to be forged by mechanical, hydraulic or screw presses. Several keystrokes may be necessary for the material to completely fill the matrix.

3-Extraction and heat treatment

Once formed, the part is expelled and transferred to the next steps. The heat treatment and machining are carried out internally in our companies or via one of the partners of Setforge group.

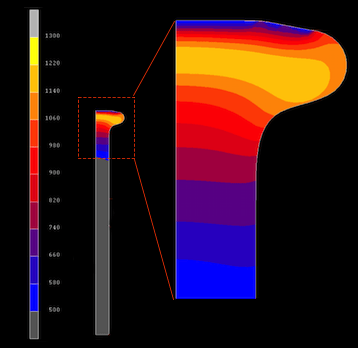

Mise en évidence des différences de températures lors de la déformation.

CHARACTERISTICS

The slug can be deformed:

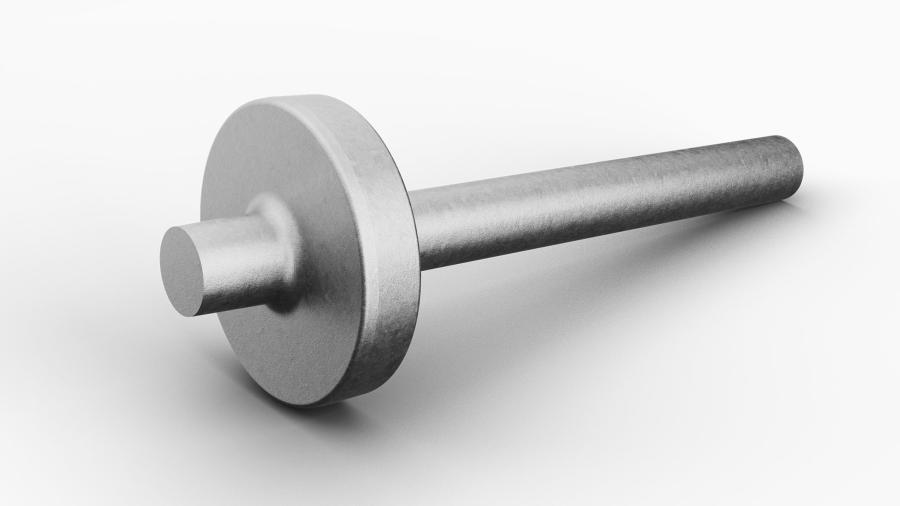

- At one end of the slug (example wheel shaft)

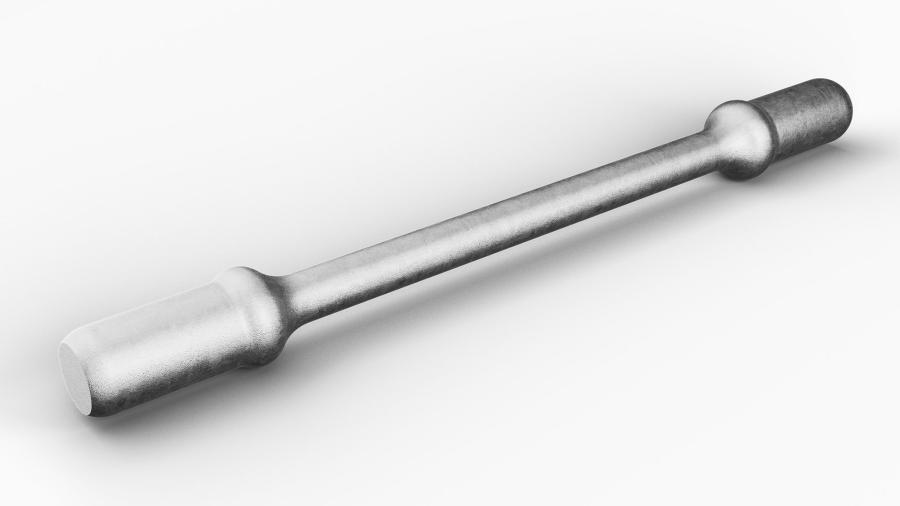

- At both ends of the slug (example torsion bar)

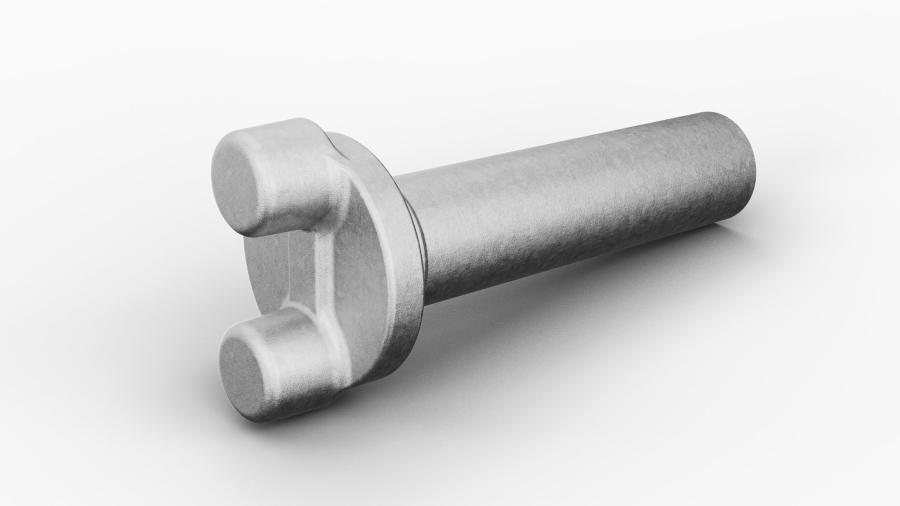

- In the center of the slug (example transmission shaft and connection)

For each configuration, all the parameters involved in the delivery of the material are controlled in order to obtain a preform perfectly suited to the forging operation.

The process makes it possible to maintain the continuity of the material fibers, thus ensuring optimum performance and resistance to fatigue.

We are able to forge all types of steels by electrical upsetting: steel, stainless steels, titanium ...

ADVANTAGES AND LIMITATIONS

STRUCTURAL INTEGRITY

The process makes it possible to obtain one-piece flange parts ensuring optimal structural integrity. It is also the only process that makes it possible to achieve a deformation ratio of up to 20 times the initial diameter of the slug.

PERFORMANCE

Electrical upsetting makes it possible to maintain the continuity of the material fiber, allowing superior mechanical characteristics to be obtained compared to machining or welding solutions.

ENERGY SAVINGS

Only the part to be deformed is heated by electrical conduction. The process emits little CO2 and is energy efficient.

MATERIAL SAVINGS

The process is optimized to get as close as possible to the dimensions of the finished part. Burr production is limited and all of the material entered is used.

REDUCTION OF MACHINING OPERATIONS

As close as possible to the final dimension of the part, the process makes it possible to limit the number of times in turning.

ELECTRICAL UPSETTING BY SETFORGE

Setfrorge has two companies specialized in electrical upsetting: Setforge Electroforge and Setforge Barriol & Dallière. Active in the automotive, public works, agriculture, aeronautics, rail, textile and energy sectors, together they cover a wide spectrum of components up to 200 kg for small, medium and large production series.

Wheel shaft

TRUCKS

Torsion bar

RAILWAY

Wheel shaft

AUTOMOTIVE

Thermowell

OIL&GAS

Drive shaft

TEXTILE

Hydraulic Coupling

AERONAUTICS

Would you like to know more about electrical upsetting?

OUR TEAMS ARE AT YOUR DISPOSAL!