COLD FORGING

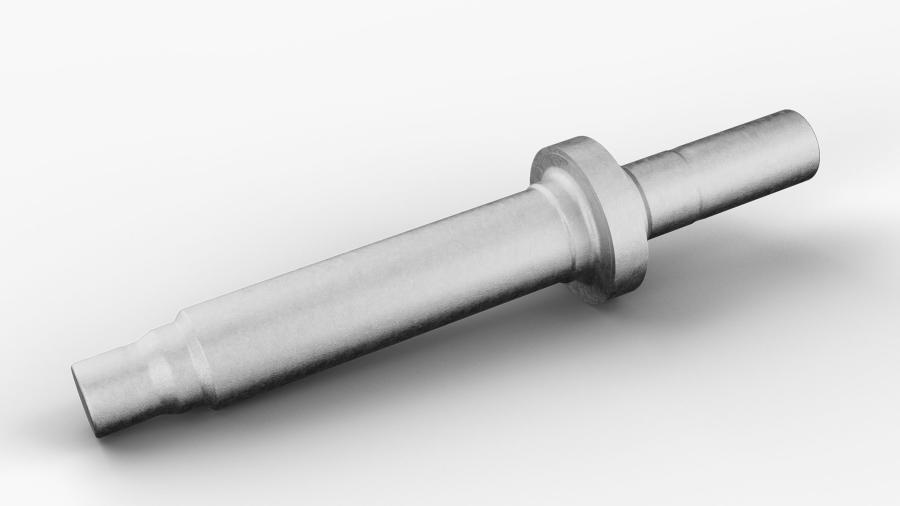

Setforge is a well-known specialist in the cold forging of drive shafts for all sectors. Discover this unique process.

A PRECISION PROCESS

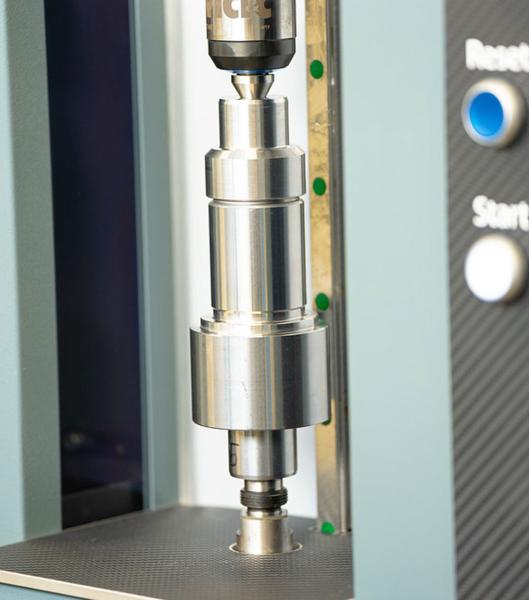

Cold forging consists of deforming a metal material at room temperature by applying very high pressure. The slug is placed in a die and then compressed by the action of a press until it fits into the desired shape. Depending on the geometric complexity of the component, several operations may be required to gradually deform the metal.

Particularly suitable for axisymmetrically shaped components, such as shafts, this process is particularly competitive and allows the final dimensions of the product to be approached.

Setforge is one of the European specialists in this process. We are able to produce parts for all production volumes and weighing up to almost 30Kg for a maximum length of 800 mm. A unique capacity on the market!

PRODUCTION AND CHARACTERISTICS

The cold forging process is particularly suited to high production rates and is ideally suited to the needs of high volume industries such as automotive. In the absence of heating the billets, the pressure exerted by the presses is higher than with other forging processes and therefore requires the use of powerful presses.

1-Cutting the slugs

Not all steel grades are suitable for cold forging. The carbon content must be less than 0.5% and the work hardening rate must be acceptable.

The bars are delivered softened by a suitable heat treatment carried out by the steelmaker.

2-Lubrication

A lubricant is applied to the slug to prevent it from sticking to the die and to make it slide more easily. The friction forces are extremely high.

During the process, the workpiece can reach a temperature of almost 250°C!

3-Forging operations

The slug is placed successively in several dies in order to gradually reach the desired shape.

The pushing force is applied by hydraulic or mechanical presses, vertical or horizontal.

4-Delivery

Cold-forged parts may not require further heat treatment.

In this case, they are machined directly in our companies or shipped to our customers.

CHARACTERISTICS

The internal structure of the metal is organised in fibres. This "fibration" is the result of the tightening and reorientation of the crystals during the working (plastic deformation) of a metal part. The control of the orientation of these fibres makes it possible to obtain very high mechanical characteristics.

Cold forging allows perfect control of the fibre pattern adapted to the geometry of the part and oriented according to the mechanical constraints of use. Unlike bar machining, the fibres are not cut. As a result, cold forged parts benefit from optimal fatigue life, allowing them to be used in the most critical applications.

The dimensional control of cold forging allows forging without burrs or waste material. In addition to the material savings, the parts do not have a deburring plate, which facilitates machinability.

Cold forging is not suitable for low ductility steels. The percentage of carbon must be less than 0.5%. Common cold forgeable steels are :

- 17CrNiMo6

- 42CrMo4

- 16MnCr5

- 20MnCrS4

BENEFITS AND LIMITATIONS

MATERIAL SAVINGS

The weight of material used is equal to the weight of the finished part. No deburring is required, unlike other processes.

DIMENSIONAL ACCURACY

The process allows perfect control of the final dimensions of the part. The tolerance on the finished diameter is only +/-0.3 mm.

PERFORMANCE

Thanks to a controlled orientation of the fibre and a high degree of work hardening, the mechanical characteristics are improved and the part benefits from an optimal weight/performance ratio.

SIMPLIFIED MACHINING

Cold forging provides a "clean" surface finish with tolerances close to the final dimensions of the component. Material losses are limited and machining times are reduced.

ENERGY SAVING

The absence of heating phases makes cold forging a particularly low CO2 and energy efficient process.

LIMITED GEOMETRY

Due to the high stresses applied to the material, cold forging is not suitable for complex part geometries. The process is reserved for axisymmetric parts such as shafts.

COLD FORGING AT SETFORGE

Seforge has two companies specialising in cold forging. Setforge Near Net, which is mainly active in the automotive sector, is able to produce several million parts per year, with parts weighing up to 4 kg. Setforge Extrusion also works in the public works and agricultural sectors and is able to produce cold forged parts up to 30 kg and 800 mm in length for all types of transmission.

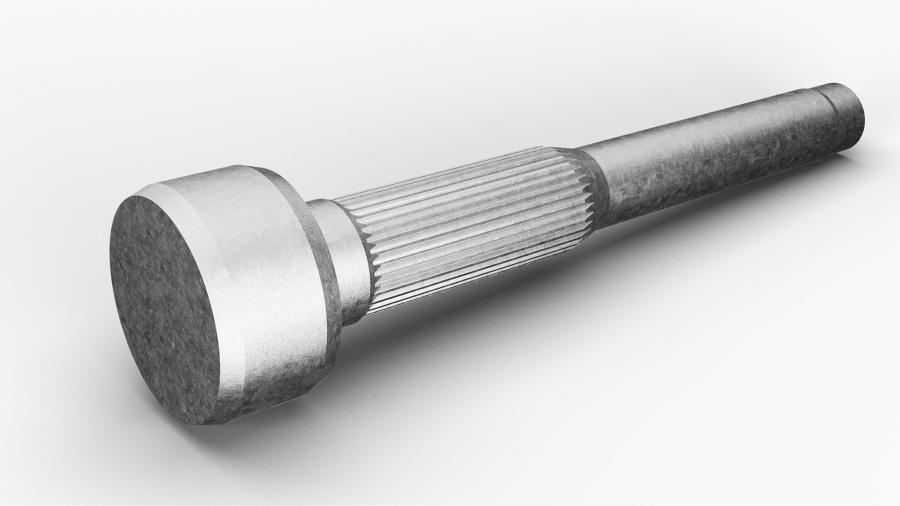

Gearbox secondary shaft with forged splines

AUTOMOTIVE

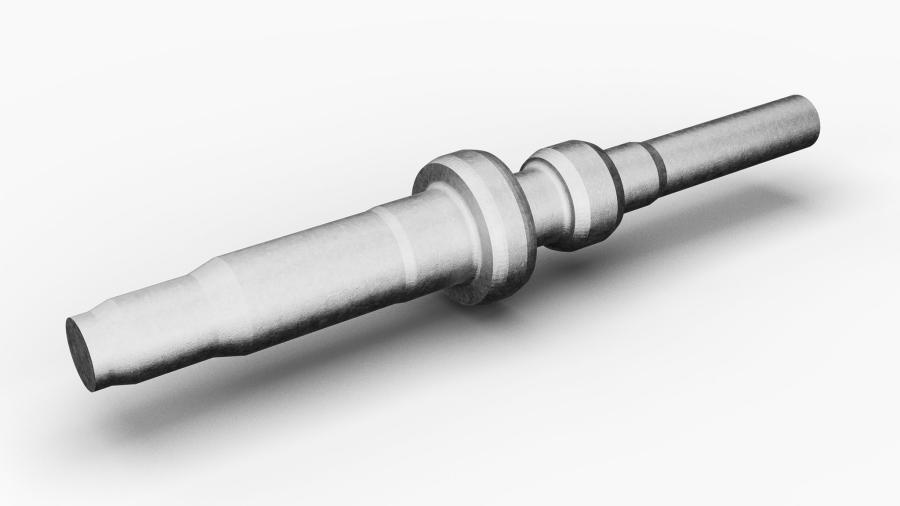

Gearbox input shaft with forged undercut

AUTOMOTIVE

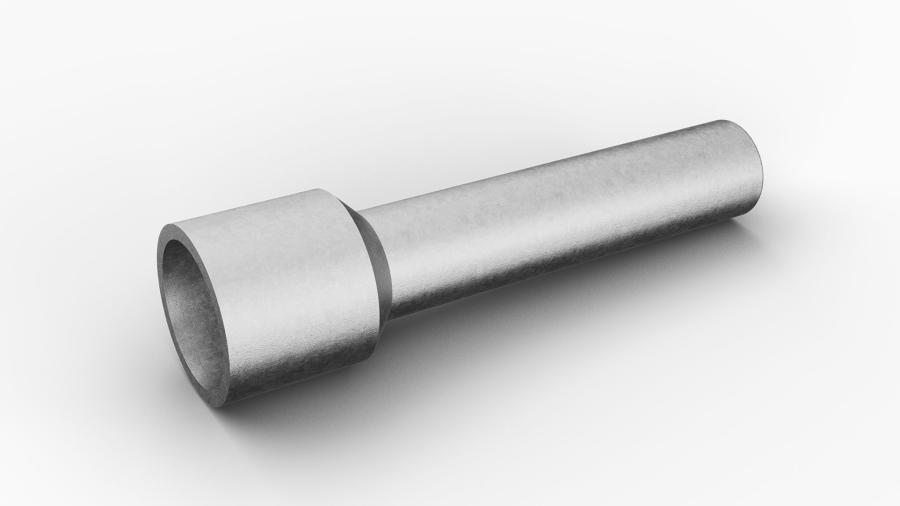

Hollow shaft gearbox

AUTOMOTIVE

Rotor Shaft

E-MOBILITY

Would you like to know more about cold forging?

OUR TEAMS ARE AT YOUR DISPOSAL!