Setforge Electroforge is the French Leader in Electrical Upsetting

The high industrial demand for complex mechanical components and the constantly changing requirements in leading industrial sectors as automotive and aeronautic have put a lot of pressure on production efficiency. Electrical upsetting is the manufacturing process that has the most benefited from this evolution. Favored for its high productivity and low cost, electrical upsetting is mainly used for the manufacture of transmissions, hydraulic couplings, shafts for automotive, aerospace and also many other business fields. The technique forms a local enlarged diameter on a bar, and the preformed workpiece can then be forged without further heating. It is usually used as a preform process; the local enlarged diameter can be made in one end, in the middle or in both ends of the bar.

Setforge Electroforge is one of the 9 forging subsidiaries of Setforge, part of Farinia Group, specialized in material transformation. Setforge Electroforge is the French leader in the manufacture of forging parts in steel, stainless steel and also titanium with electrical upsetting process.

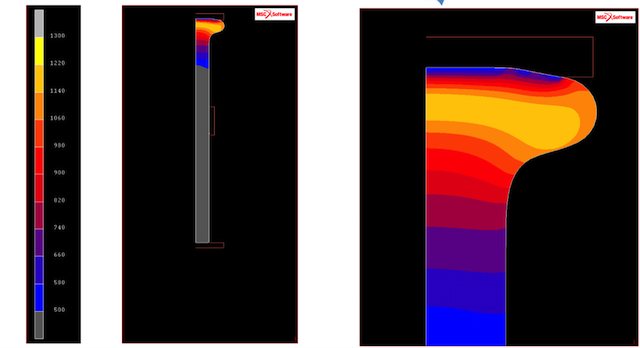

Electrical Upsetting Process Simulation

Setforge Electroforge and Its Expertise

Gilles Le Moal, the director of Setforge Electroforge describes the process of electrical upsetting as “the only manufacturing process allowing a wide variation of the original diameter of the bar and then very well adapted for the production of transmision shafts (the plate diameter is up to 5 or 6 times the shaft section), maintaining the continuity of the grain flow of the raw material.”

For example the process starts with a bar 300mm length and diameter from 20 to 50mm. After electrical upsetting and final forging, we will be able to reach a plate with a diameter up to 150mm or 200mm. This forging process, with state-of-the art equipment, is the only one able to reach such ratio and save huge quantity of raw material and machining costs. As only the local area, which has to be forged is heated, there is also a minimum quantity of energy used. The company has been continuously upgrading the production process with lean and sigma 6 approaches.

Electrical Upsetting – Technical Characteristics

Electrical upsetting process can be described by applying an axial force on a bar, which is directly heated in the same time by conduction. The current is directly passed through the part by contact, between one end of the bar and a moving clamping electrode (jaws). The heating is made on a partial length of the bar, avoiding to heat the complete bar. An accumulation of material is then created at the extremity of the bar.

All parameters to control the raw material deformation (axial force, current intensity, material flow, top die electrode and claws positions) are under control to obtain the planned preform shape before forging the final part. It has excellent repeatability and quick set-up of the production process.

The big advantage of this technique is the fact that the part can be directly forged with no further heating and then obtain a bigger final part diameter than the original diameter of the bar. The technique can be performed at one extremity, both ends, or in the middle of the bar.

Particularities

As with any other metalworking process, electrical upsetting should be only performed while strictly following some predefined regulations as:

- The respect of the maximum heating for each raw material.

- Bar surface must be free of defects to insure good electrical contact.

- The life time of the contact tools (claws) is directly linked to the contact surface quality.

Components Manufactured With Electrical Upsetting

Electrical upsetting can find some applications in the aerospace, automotive and many other industrial sectors. Discover examples of Electroforge components manufactured with electrical upsetting from steel, stainless steel and titanium:

- Aeronautic Hydraulic Couplings

- Automotive Shaft

- Off-Highway Transmission Shaft

- Agriculture PTO Shaft

- Agriculture Axle Shaft

- Off-Highway Axle Shaft

- Off-Highway Cylinder Piston Rod

- Trucks Axles Spindle

- Trucks Transmission Drive Pinion

- Trucks Chassis Anti-roll Bar

- Oil & Gas Flange

- Ultrasonic sensors

Advantages of Electrical Upsetting Compared to Machining

A component manufactured with electrical upsetting features numerous advantages compared to a machined part as:

- Maintained grain flow

- Enhanced mechanical characteristics

- Cost saving on the purchase of the raw material (for all materials but most of all for expensive material as Titanium)

- Cost saving in machining time

Indeed, upset components feature shape and size that are as close as possible to these of the finished parts. Thus, the overall machining time of the part is significantly reduced.

Dedicated to innovation, Setforge Electroforge offers its customers a highly optimized and cost efficient production process. We work close with the customer’s design office to deliver a component of best mechanical properties for highly reliable performance. Furthermore, our team will be able to provide shortly a high-quality pre-machining service.